When your Hoover vacuum brush roll stops spinning, cleaning halts fast—dust lingers, hair stays embedded in carpet, and your floors don’t look any better. The good news: most “Hoover vacuum not spinning” problems are caused by simple issues like a tripped brush reset, tangled hair, or a worn belt. A quick fix is to power off, flip the vacuum, remove the base plate, clear hair from the brush roll, and press the brush reset button (if your model has one). That alone solves a large percentage of cases.

In this complete guide, you’ll learn all the common causes, how to diagnose and fix brush roll issues on uprights and stick vacs, and how to prevent it from happening again. We’ll cover multiple solution paths—from easy resets to belt replacement and motor checks—so by the end, you’ll have your Hoover spinning like new.

Common Causes of a Hoover Vacuum Not Spinning

- Brush roll jammed with hair/threads: The most frequent cause. Hair wraps around the brush, stopping rotation.

- Tripped brush roll reset/thermal fuse: Overload triggers a safety cutoff on many Hoover models.

- Worn, stretched, or broken belt: The drive belt loses tension or snaps, disabling the brush.

- Incorrect floor setting or brush switch off: Brush head disabled in Hard Floor mode or the brush control is off.

- Clogged brush housing or end caps: Debris in bearings/end caps prevents smooth rotation.

- Faulty brush roll motor or clutch (model-dependent): Less common, but possible if belts and brush are fine.

- Loose or misaligned belt after maintenance: Belt slipped off the motor spindle or brush roll.

- Low battery or not in “Carpet” mode (cordless models): Brush disables to save power.

- Internal wiring issue or failed PCB (for some stick vacs): Rare, but occurs after impacts or liquid exposure.

How to Fix a Hoover Vacuum Not Spinning

Below are four methods, from the fastest to more advanced. Check your model number (e.g., Hoover WindTunnel, T-Series, PowerDrive, React, H-Free/HB series, ONEPWR cordless) to match steps as needed. Always unplug corded vacuums or remove the battery on cordless before working.

Method 1: Quick Reset and Basic Checks

Diagnosing the Issue

- Symptoms: Brush roll not turning, burning smell before it stopped, “Brush” light off, or “Check Brush” indicator lit.

- Time: 5–10 minutes

Fix Steps

- Power off and unplug. For cordless, remove the battery.

- Set floor mode to Carpet and ensure any “Brush On/Off” button is ON.

- Locate the brush roll reset button (commonly on the nozzle head or near the back of the brush housing). Press firmly once.

- Inspect the brush area:

– Flip the vacuum and look for wrapped hair, thread, or string. Remove visible debris by hand or with scissors.

– Spin the brush roll by hand: it should rotate freely. If stiff, proceed to Method 2. - Check for blockages:

– Remove the nozzle plate (usually 2–6 Phillips screws).

– Clear debris around the brush, belt path, and air channel.

Testing

- Plug in/reinstall battery.

- Set to Carpet mode and power on. Tilt the handle back so the brush engages (some models only spin when reclined).

- If the brush spins, you’re done. If not, continue to Method 2.

Method 2: Deep Clean the Brush Roll and End Caps

If the brush feels rough to turn, hair may be lodged in the end caps/bearings.

Diagnosing the Issue

- Symptoms: Brush turns but feels gritty or stiff; intermittent spinning; squeaking.

- Time: 15–25 minutes

Fix Steps

- Unplug/remove battery.

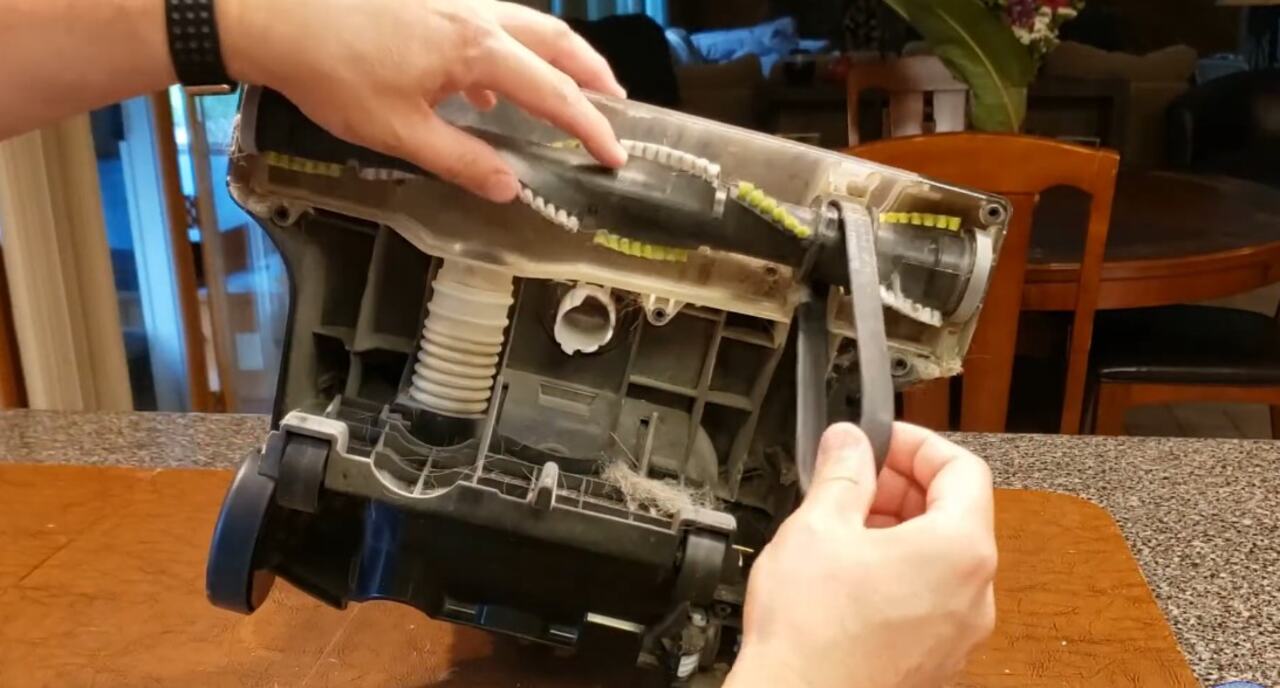

- Remove the base plate and lift out the brush roll and belt.

- Clear hair from bristles using scissors or a seam ripper. Avoid cutting bristles.

- Remove end caps (some pull off; others have small screws). Note the order of washers/spacers.

- Clean bearings:

– Pull out any hair/thread from the end cap cavities.

– Wipe bearings with a dry cloth. If accessible, add a tiny drop of light machine oil to metal bearings only. Do not lubricate plastic bushings excessively. - Inspect the belt:

– If cracked, glazed, stretched, or loose, replace (see Method 3). - Reassemble:

– Refit end caps, align the belt on the brush roll pulley and motor spindle.

– Ensure belt sits centered and not twisted.

– Reinstall base plate.

Testing

- Reset the brush (if your model has a reset button).

- Power on in Carpet mode and recline the handle.

- If spinning is weak or non-existent, move to Method 3.

Method 3: Replace the Drive Belt

Belts wear out and are the most common mechanical failure. Hoover belts typically cost $5–$12. Use the exact belt type/number for your model (e.g., Hoover 38528034, 562289001, or model-specific belt sets—check your user manual or Hoover’s parts site).

Diagnosing the Issue

- Symptoms: Brush not spinning though motor runs; burning smell; belt looks loose, shiny, or snapped; brush spins by hand but not under power.

- Time: 15–30 minutes

Fix Steps

- Unplug/remove battery.

- Remove base plate and pull out the brush roll.

- Remove the old belt. Check the motor spindle for residue; clean with a dry cloth.

- Install the new belt:

– Loop the belt around the motor spindle first.

– Feed the brush roll through the belt and seat the belt on the brush pulley.

– Tension: The belt should be snug. You’ll need to stretch it slightly to fit. This is normal. - Seat the brush roll:

– Align end caps with the housing slots. Make sure the belt is not pinched or twisted. - Reinstall base plate.

Testing

- Press brush reset.

- Power on, recline, and test on Carpet mode.

- If the belt immediately fails or the brush still doesn’t move, the brush motor/clutch may be faulty (Method 4).

Method 4: Electrical and Motor Checks (Advanced)

Some Hoover models drive the brush with a dedicated motor in the nozzle (especially on newer uprights and stick/cordless vacs). If belts and mechanical parts are good, the motor or control may be at fault.

Diagnosing the Issue

- Symptoms: No spinning despite good belt and free brush; no motor noise from the nozzle; brush LED indicator shows fault; issue appeared after a blockage or overheating; or after liquid exposure.

- Time: 20–45 minutes (inspection), longer if replacing parts

Fix Steps

- Verify power and settings:

– On corded models, ensure the main motor runs at full power. On cordless, fully charge the battery and select a high suction mode with brush enabled. - Inspect wiring and connectors:

– Remove nozzle housing screws.

– Check for loose connectors from PCB to motor and from main body to nozzle.

– Look for burned components or scorched smell on the small PCB. - Test brush motor (qualified users):

– If comfortable and safe, use a multimeter to check continuity of the motor windings and voltage at the motor when the brush is enabled.

– No voltage to motor suggests a control/wiring issue; voltage present but no spin suggests a failed motor. - Replace the faulty component:

– Order a replacement nozzle motor, brush roll assembly, or complete floorhead as per model number.

– Many Hoover floorheads are modular and can be swapped with a few screws.

Warning: Opening motor housings may void warranty. If in warranty, contact Hoover support before proceeding.

Testing

- Reassemble, reset, and test in Carpet mode. Ensure the brush spins smoothly without unusual noise.

How to Prevent Future Spinning Issues

- Empty the bin/bag regularly: Overfilled bins increase load and heat, triggering shutoffs.

- Clean the brush roll weekly if you have pets or long hair: Prevents tight wraps and motor strain.

- Replace belts every 6–12 months (or sooner with heavy use): Cheap and prevents downtime.

- Keep filters clean: Clogged filters reduce airflow, causing overheating and automatic brush cutoff.

- Use correct floor mode: Disable brush on hard floors if your model requires it; enable on carpet.

- Avoid vacuuming wet material: Liquids damage motors, belts, and electronics.

- After clearing clogs, press the brush reset button before resuming.

Pro Tips

- Keep a spare belt on hand: Replace immediately if performance drops—no wait time.

- Cut hair along the brush roll grooves: Many Hoover brushes have channels to safely insert scissors.

- Check the belt path when reassembling: A twisted belt will burn and snap quickly.

- Watch for warning lights: Some models show a red “Brush” or “Check Brush” LED when overloaded—stop and clear immediately.

- Recline to activate: Several Hoover uprights only spin the brush when the handle is tilted back.

- Use a seam ripper instead of scissors: It’s faster and less likely to cut bristles.

- If the brush slows on thick carpet: Use a higher pile setting or reduce suction if your model allows.

When to Call a Professional

- Electrical smell, smoke, or repeated tripping: Could indicate a failing motor or short.

- The brush motor receives power but doesn’t spin: Likely a seized motor or failed bearings—replacement needed.

- Repeated belt breakage: Often due to misalignment, seized end cap, or incorrect belt type.

- Liquid damage: Requires internal cleaning and electrical inspection.

- In-warranty vacuums: Contact Hoover support for authorized repair or replacement.

Typical Costs:

– Belt: $5–$12

– Brush roll assembly: $20–$45

– Nozzle motor/floorhead: $40–$120

– Shop labor: $50–$100+

Warranty Notes:

– Using non-OEM parts or opening the motor housing can void coverage. Check your manual and register your product for streamlined service.

FAQ

Q: Why did my Hoover brush stop spinning suddenly?

A: Most likely due to hair jam or belt failure. Overheating may have tripped the brush reset. Clear the brush, press the reset button, and check/replace the belt if needed.

Q: Where is the brush reset button on Hoover vacuums?

A: On many Hoover uprights, it’s on the nozzle head or near the brush housing—often a small red or black button. Consult your model manual or Hoover’s support page for exact location.

Q: How do I know if my belt is bad?

A: Signs include a burning rubber smell, visible cracks/glazing, excessive slack, or the brush not turning while the main motor runs. If in doubt, replace—the cost is low.

Q: My Hoover is cordless—does low battery affect the brush?

A: Yes. Many ONEPWR and stick models reduce or disable brush roll at low battery to conserve power. Fully charge and ensure you’re in Carpet/Turbo mode.

Q: The brush spins by hand but not under power. What next?

A: Check for a slipped or stretched belt, verify correct installation, and ensure the handle is reclined. If the belt is fine, test the brush motor and wiring.

Q: Can I lubricate the brush roll?

A: Only a tiny drop of light oil on metal bearings if accessible. Do not grease belts, pulleys, or plastic bushings. Excess lubricant attracts dust and can damage parts.

Q: How often should I replace the belt?

A: Every 6–12 months for average use, or sooner with pets/high hair load. Replace immediately if you notice slipping or glazing.

Alternative Solutions

If repeated issues persist or parts are unavailable, consider upgrading or changing tool types.

| Solution | Pros | Cons | Best For |

|---|---|---|---|

| Replace entire floorhead | Quick swap, restores performance | Higher cost than belt | Models with worn motors/PCB faults |

| Switch to a tangle-free brush model | Less hair wrap, lower maintenance | May require new vacuum | Homes with long hair/pets |

| Use a hard-floor tool (brushless) | No belt/brush issues | Not for carpets | Hard floors, area rugs only |

| Professional repair service | Expert diagnosis | Labor costs | Out-of-warranty complex faults |

Get Your Hoover Vacuum Working Again

Following this guide, you now have multiple solutions to fix your Hoover vacuum not spinning:

– Quick reset and mode checks

– Deep cleaning of the brush roll and end caps

– Belt inspection and replacement

– Advanced motor and wiring diagnostics

Don’t let a stuck brush stop your cleaning routine. Start with the fast checks, replace the belt if needed, and your Hoover will be back to lifting dirt from carpets in no time. Still stuck? Share your model number and symptoms in the comments for personalized advice, and bookmark this guide for future maintenance. With a few simple habits, you’ll prevent “Hoover vacuum not spinning” headaches for good.