Nothing’s more frustrating than pulling out your vacuum cleaner for a quick cleanup, only to find the roller brush isn’t spinning, leaving dirt and debris behind like a stubborn guest who won’t leave. If you’re dealing with a vacuum roller not spinning issue, you’re not alone—it’s a common problem with upright vacuums from brands like Shark, Dyson, or Hoover that can halt your cleaning routine in its tracks. The good news? A simple quick fix like checking for blockages or resetting the vacuum often gets things moving again in under 5 minutes, providing immediate relief without needing tools or replacements.

In this comprehensive guide, we’ll go far beyond that initial troubleshooting step to explore all the potential causes, multiple repair methods from DIY basics to more advanced tweaks, and long-term prevention strategies. By the end, you’ll have the confidence and knowledge to diagnose and resolve your vacuum roller not spinning problem completely, saving you time, money, and the hassle of a trip to the repair shop. Whether it’s a belt issue, motor glitch, or something else, we’ll cover it all with step-by-step instructions tailored for everyday users.

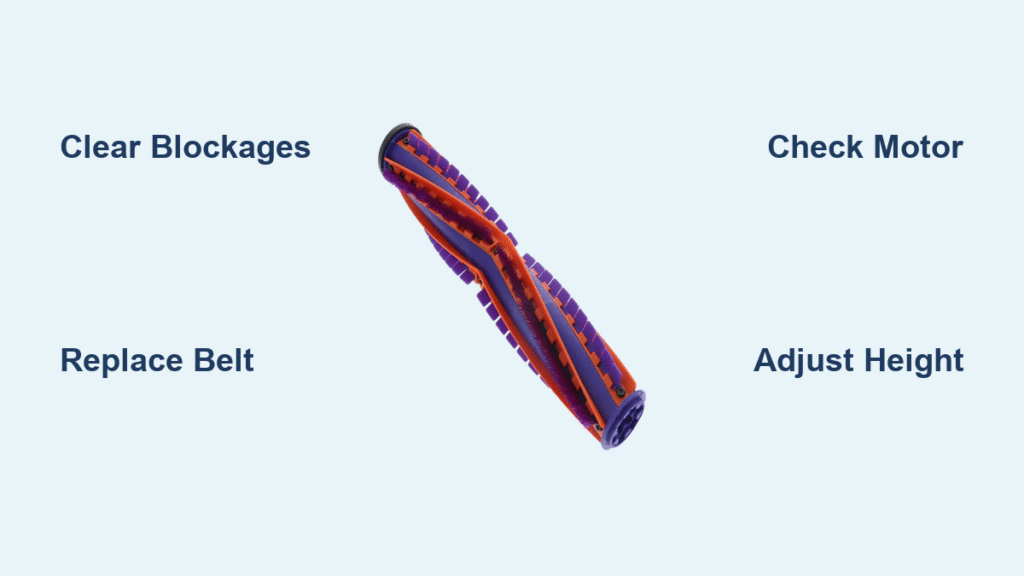

Common Causes of Vacuum Roller Not Spinning

Understanding why your vacuum’s roller isn’t spinning is the first step to fixing it. This issue typically affects the brush roll (also called the beater bar) in upright models, which is responsible for agitating carpets to lift dirt. Based on user reports and manufacturer guidelines from brands like Shark and Dyson, here are the most frequent culprits. We’ll break them down with explanations to help you identify what’s going on with your specific model.

Blockages or Debris Jams

The top cause of a vacuum roller not spinning is something as simple as hair, strings, or pet fur tangled around the roller brush. Over time, these build up and prevent free rotation, especially in high-traffic homes with long-haired pets or lots of rugs. If the roller feels stuck when you manually turn it (with the vacuum unplugged, of course), this is likely your issue. Debris can also jam the belt or gears connected to the roller, stopping motion entirely.

Worn or Broken Drive Belt

Many vacuums use a rubber drive belt to connect the motor to the roller brush. If this belt is stretched, cracked, or snapped—often due to age or overuse—the roller won’t receive power from the motor. This is common in models like the Shark Navigator or Hoover WindTunnel after 1-2 years of regular use. Signs include a burning smell during operation or visible wear if you inspect underneath the vacuum.

Motor or Switch Malfunctions

If the vacuum powers on but the roller doesn’t engage, the problem might lie in the motor brush roll switch or the main suction motor. A faulty switch (a small lever or button that activates the brush roll) can fail from dust buildup or electrical wear. In rarer cases, the motor itself could be overheating or failing, which is more serious and often accompanied by unusual noises or reduced suction overall.

Overloaded Safety Features or Height Adjustment Issues

Modern vacuums have built-in safety mechanisms, like thermal cutoffs, that stop the roller if the unit overheats from clogs or prolonged use on thick carpets. Incorrect height adjustment on the nozzle can also cause excessive resistance, making the roller bind and stop spinning. This is especially true for adjustable models where the brush roll height isn’t set properly for your floor type.

How to Fix Vacuum Roller Not Spinning

Now that you’ve pinpointed the likely cause, let’s dive into actionable solutions. We’ll cover three progressive methods: a quick DIY check for beginners, a belt replacement for intermediate users, and advanced motor troubleshooting. Start with Method 1 and work your way down. Always unplug the vacuum before any repairs to avoid electrical hazards—safety first! These steps are generalized but apply to most upright models; consult your model’s manual for specifics.

Method 1: Clear Blockages and Reset the Vacuum (Quick Fix, 5-10 Minutes)

This is the easiest starting point for a vacuum roller not spinning, as it resolves up to 70% of cases without tools.

-

Unplug and Flip the Vacuum: Turn off and disconnect the vacuum from power. Lay it on its side or back to access the bottom plate. This exposes the roller brush and belt area.

-

Remove the Brush Guard and Inspect: Use a screwdriver (usually Phillips) to unscrew the plate covering the roller—most models have 2-4 screws. Gently pull out the roller brush. Look for tangles: hair wrapped around the bristles or ends.

-

Clean and Untangle: Use scissors or a seam ripper to cut away debris. Rotate the roller by hand to ensure it spins freely. Wipe the brush with a damp cloth and vacuum any loose dirt from the housing.

-

Reassemble and Test: Snap the roller back in, secure the plate, and plug in the vacuum. Turn it on low and check if the roller spins. If not, press the brush roll on/off switch (often on the handle or foot pedal) to engage it. Run a test on a carpet for 1-2 minutes.

If it still doesn’t spin, proceed to the next method. Warning: Never force the roller; this could damage internal components.

Method 2: Replace the Drive Belt (Intermediate Fix, 15-30 Minutes)

A worn belt is a frequent reason for a vacuum roller not spinning, and replacing it is straightforward with a $5-10 part from Amazon or the manufacturer’s site.

-

Gather Supplies: You’ll need a new belt (match your model, e.g., Shark part #102FFJ for Navigator series), screwdriver, and possibly pliers. Refer to your manual for the exact belt type—flat or V-shaped.

-

Access the Belt Area: Follow Step 1 from Method 1 to remove the bottom plate and roller. Note how the old belt loops around the motor pulley and roller ends.

-

Remove the Old Belt: Slip the belt off the pulleys carefully. If it’s snapped, pieces might be inside—use tweezers to extract them. Clean the pulleys with a soft brush to remove residue.

-

Install the New Belt: Stretch the new belt over the motor pulley first, then hook it onto the roller ends. Ensure it’s not twisted. Reinsert the roller, aligning the belt properly.

-

Test Thoroughly: Reassemble, plug in, and run the vacuum. Listen for smooth operation without slipping sounds. Vacuum a small area and check for even agitation on carpets.

Pro Tip: Replace the belt every 6-12 months for preventive maintenance. If the belt snaps immediately after replacement, the motor pulley might be worn—move to Method 3.

Method 3: Diagnose and Address Motor or Switch Problems (Advanced Fix, 30-60 Minutes)

For persistent vacuum roller not spinning issues, this method targets electrical components. If you’re not comfortable with wiring, skip to the Professional Help section.

-

Check the Brush Roll Switch: Locate the switch on the vacuum’s base or handle. Clean around it with compressed air to remove dust. Test continuity with a multimeter—if it doesn’t click or show power, replace it (costs $10-20).

-

Inspect the Motor: With the vacuum disassembled, visually check the motor for burnt wires or overheating signs (discoloration). Spin the motor shaft by hand; it should turn freely.

-

Reset Safety Features: Let the vacuum cool for 30 minutes if it was recently used. Some models have a reset button near the motor—press it. For thermal overload, ensure vents are dust-free.

-

Basic Electrical Test: If you have a multimeter, test for power at the motor terminals when switched on. No voltage? The issue is upstream in the cord or switch. For motor replacement, it’s often cheaper to buy a new vacuum unless under warranty.

-

Reassemble and Monitor: Put everything back, test on various surfaces, and note any unusual heat or noise. If the roller spins intermittently, it could indicate a failing motor bearing—consider professional service.

Important: Working with electrical parts risks shock or voiding warranty. If your vacuum is under 1-year coverage, contact the manufacturer first.

Preventing Future Vacuum Roller Issues

Once you’ve fixed your vacuum roller not spinning problem, prevention is key to avoiding repeats. Regular upkeep extends your vacuum’s life by 2-3 years and keeps performance optimal.

-

Clean the Roller Monthly: Remove and inspect the brush roll every 4 weeks, especially in pet-heavy homes. Use a wide-tooth comb for detangling to prevent buildup.

-

Maintain Proper Height Settings: Adjust the nozzle height for your floors—low for carpets, high for hardwoods—to reduce strain on the belt and motor.

-

Empty the Bin Frequently: Overfilled dirt cups increase suction resistance, indirectly stressing the roller. Empty after every use or when 2/3 full.

-

Store Upright and Dry: Avoid wrapping the cord tightly, which can damage wiring. Keep the vacuum in a cool, dry place to prevent belt degradation.

Follow a simple maintenance schedule to stay ahead:

| Frequency | Task | Duration |

|---|---|---|

| Weekly | Empty bin and wipe exterior | 5 minutes |

| Monthly | Clean roller and check belt | 10-15 minutes |

| Every 6 Months | Inspect motor vents and replace belt if worn | 20 minutes |

| Annually | Full disassembly and deep clean | 30-45 minutes |

By incorporating these habits, you’ll minimize downtime and ensure your vacuum runs smoothly for years.

Pro Tips for Vacuum Roller Maintenance

To take your vacuum care to the next level and avoid common pitfalls with vacuum roller not spinning issues, here are expert-recommended tips based on technician insights from sites like iFixit and manufacturer forums:

-

Use the Right Accessories: Opt for pet hair removal tools or crevice attachments to prevent debris from reaching the roller. Avoid vacuuming large objects like twist ties that can jam it instantly.

-

Monitor for Early Warning Signs: Listen for grinding noises or reduced suction before the roller stops completely—these indicate belt slippage. Address them immediately to avoid costly motor damage.

-

Lubricate Sparingly: For some models (check manual), apply a drop of silicone lubricant to the roller ends annually. Never use oil, as it attracts dirt.

-

Upgrade to Self-Cleaning Rollers: If your vacuum is older, consider models with anti-hair wrap technology (e.g., Dyson’s Tangle-Free Turbine) to reduce tangles by 90%.

-

Test on Different Surfaces: After fixes, run diagnostics on carpet, hardwood, and rugs to ensure consistent spinning—adjustments might be needed per floor type.

-

Avoid Overloading: Don’t vacuum for more than 20-30 minutes continuously on high-pile rugs to prevent overheating.

-

Track Usage: Log cleaning sessions in a app or notebook to predict when belts need replacement, optimizing longevity.

Common mistakes to dodge: Forcing a stuck roller (breaks belts), ignoring pet hair buildup (leads to frequent jams), or using generic belts (they stretch faster than OEM parts).

When to Call in Professional Help

While DIY fixes resolve most vacuum roller not spinning problems, some situations warrant expert intervention to avoid further damage or safety risks.

Signs you need a pro: The motor smells burnt, there’s visible sparking, the vacuum won’t power on at all, or repeated belt failures occur (indicating pulley misalignment). If your model is high-end (e.g., Dyson costing $300+), professional service preserves warranty.

Look for certified technicians via the manufacturer’s site (e.g., Shark’s authorized centers) or services like uBreakiFix. Check reviews for quick turnaround (under 48 hours) and transparent diagnostics. Typical costs: $50-100 for belt/motor checks, $100-200 for full repairs. Factor in shipping if no local option.

Warranty tip: Most vacuums have 1-5 year coverage for parts like belts and motors—keep receipts and register online to claim free fixes.

FAQ

Q: Why is my Shark vacuum roller not spinning but suction is fine?

A: This usually points to a belt or switch issue rather than a full clog. Follow Method 2 to replace the belt, as Shark models like the NV series rely heavily on it for brush engagement. If suction is strong, the motor is likely okay, so focus on the roller assembly.

Q: Can I fix a vacuum roller not spinning on a Dyson without tools?

A: Yes, for basic blockages—unplug, remove the soleplate (tool-free on many models), and untangle debris. Dysons often have a red tab for easy brush removal. For belts, tools are needed, but it’s a 10-minute job.

Q: How do I know if it’s the motor causing the roller not to spin?

A: If the vacuum runs but the roller doesn’t engage even after cleaning and belt replacement, test the switch with a multimeter or listen for motor hum without brush action. Replacement motors cost $50-150, but pros handle this best.

Q: Is a vacuum roller not spinning dangerous?

A: Not inherently, but it can lead to motor strain or fire risks if ignored (e.g., overheating). Always unplug before inspecting, and stop use if you smell burning rubber.

Q: What if my Hoover vacuum’s roller spins intermittently?

A: Intermittent spinning often means a loose belt or dirty switch contacts. Clean thoroughly and tighten components during reassembly. If it persists, check for worn bearings in the roller ends.

Q: Can I prevent vacuum roller not spinning in pet homes?

A: Absolutely—brush pets regularly to reduce hair, use a grooming attachment, and clean the roller bi-weekly. Models with zero-tangle brushes (e.g., Bissell Pet Hair Eraser) are ideal upgrades.

Q: How long does a vacuum belt last before causing roller issues?

A: Typically 6-12 months with daily use, but it varies by model and debris type. Inspect every 3 months; replace proactively to avoid sudden stops.

Alternative Solutions for Persistent Issues

If standard fixes don’t resolve your vacuum roller not spinning, consider these alternatives. They might involve product swaps or workarounds when repairs aren’t feasible.

| Solution | Pros | Cons | Best For |

|---|---|---|---|

| Buy a Replacement Roller Assembly | Exact fit, restores full function quickly | Costs $20-50, requires basic tools | Users with minor wear but intact motors |

| Switch to a Beltless Vacuum Model (e.g., Dyson Ball) | No belts to break, easier maintenance | Higher upfront cost ($200+), heavier design | Frequent users tired of belt hassles |

| Use a Manual Brush Tool Temporarily | Cheap ($10), no electricity needed | Less efficient for large areas, manual effort | Quick spot cleans while waiting for parts |

| Professional Rebuild Kit | Includes all parts, guided instructions | Time-consuming (1-2 hours), not for beginners | Tech-savvy owners extending old vacuums’ life |

For example, if belts keep failing, upgrading to a direct-drive model eliminates the issue entirely but weighs the investment against your vacuum’s age.

Solve Your Vacuum Roller Not Spinning Problem Today

Armed with this guide, you’re equipped to tackle and prevent vacuum roller not spinning frustrations for good. We’ve covered everything from quick blockage clears and belt swaps to advanced diagnostics, plus prevention schedules and pro tips to keep your vacuum humming.

- Identify common causes like debris or worn belts

- Apply step-by-step fixes from simple to advanced

- Implement maintenance routines for long-term reliability

- Know when to seek professional help or explore alternatives

Don’t let a stalled roller derail your cleaning—start with the quick fix and work through the methods today. You’ll have your vacuum back in action, picking up every speck of dirt efficiently.

Have you fixed a vacuum roller not spinning issue using these steps? Share your experience or model-specific tips in the comments below to help fellow readers!