Is your Dyson DC25 vacuum refusing to stand upright and constantly falling forward? You’re not alone. The most common cause is a stuck or worn upright/tilt latch mechanism in the ball base, or debris blocking the recline lock. Quick fix: power off, lay the machine down, press the recline pedal firmly several times, then lift the handle fully upright until you hear a click. If it still won’t lock, follow the steps below.

In this comprehensive guide, you’ll learn the common causes of a Dyson DC25 not standing upright, quick and advanced methods to fix it, how to clean and lubricate the mechanism, and when to seek professional help. By the end, you’ll know exactly how to get your Dyson DC25 locking upright again and how to prevent the issue from returning.

Common Causes of a Dyson DC25 Not Standing Upright

- Upright locking latch jammed: Dust, hair, or carpet fibers clog the latch near the rear wheels or inside the ball assembly.

- Worn or broken latch spring: The small spring that pulls the latch into place can weaken or detach.

- Recline pedal linkage misaligned: The foot pedal that releases the vacuum from upright may not return fully.

- Debris in the brush head pivot: The neck/pivot where the cleaner head meets the body can bind, preventing the handle from reaching proper vertical position.

- Ball shell obstruction: A screw, zip tie, or debris lodged in the ball housing can block the locking cam.

- Damaged base plate or rear wheels: Warped parts or bent wheels can prevent the lock from engaging.

- Assembly not fully seated: After maintenance, the brush head or cyclone assembly may not be fully clicked in, affecting the lock alignment.

How to Fix a Dyson DC25 That Won’t Stand Upright

Method 1: Quick Reset and Debris Check (2–5 minutes)

Diagnosing the Issue

- If the handle won’t “click” when upright, the latch isn’t engaging.

- If the vacuum reclines too easily or can’t “catch,” likely a stuck latch or weak return from the recline pedal linkage.

Fix Steps

1) Turn off and unplug the vacuum.

2) Set the DC25 on a hard floor.

3) Press and release the recline pedal 10–15 times to free the linkage.

4) With one hand on the handle, slowly raise the handle to full upright. Use your other hand to gently nudge the cleaner head back toward the machine. Listen for a click.

5) Inspect the rear wheels area and underside around the recline pedal for hair or threads. Remove with tweezers or scissors.

6) Clean the pivot/neck where the cleaner head meets the body. Wipe away lint or grit.

Testing

- Lift the handle to upright. If it clicks and stands, the fix worked.

- If still no lock, move to Method 2.

Method 2: Clean and Lubricate the Upright Lock Mechanism (10–20 minutes)

Important: Always unplug before maintenance. Use a dry, non-staining lubricant like silicone spray or PTFE (Teflon) spray. Avoid oils that attract dust.

Diagnosing the Issue

- Latch engages intermittently or feels sticky.

- You hear scraping or the pedal doesn’t spring back crisply.

Fix Steps

1) Remove the cleaner head:

– Lay the vacuum on its side.

– Release the brush head by turning the side fasteners/knob and pulling the head away from the lower duct (check your DC25’s side locking tab; it should click out and back in).

2) Expose the latch area:

– Stand the vacuum on the ball.

– Locate the recline pedal at the rear. Follow its linkage visually into the base; you’ll see a plastic cam/latch that locks the spine when upright.

3) Clean debris:

– Use a small brush or compressed air to remove dust and hair from the pedal pivot, latch notch, and surrounding channels.

– Wipe with a dry cloth. Do not soak with water.

4) Apply lubricant:

– Lightly spray silicone/PTFE on the pedal pivot and the latch cam contact points. Avoid overspray on belts or electrical parts.

– Manually press the pedal several times to work the lubricant in.

5) Refit the cleaner head:

– Align and click the head back into place. Ensure a positive lock.

Testing

- Raise the handle upright and listen for a solid click.

- Gently pull back on the handle; it should stay locked until you press the recline pedal.

Method 3: Inspect and Realign the Recline Pedal Linkage (15–25 minutes)

Diagnosing the Issue

- The pedal feels loose, mushy, or doesn’t return.

- Vacuum only stands upright if you jiggle the pedal.

Fix Steps

1) Unplug and lay the machine down.

2) Remove the bin and cyclone:

– Press the red bin release, remove the bin, then the cyclone.

3) Remove the brush head (as in Method 2).

4) Access the linkage:

– Look behind the pedal. On the DC25, a simple plastic lever/cam system pushes the locking notch. Ensure the lever is seated on its pivot pins.

5) Reseat or adjust:

– If the lever has popped off a pivot, reseat it carefully.

– Check for cracked plastic around the pivot holes; minor cracks can be reinforced temporarily with a small zip tie as a stop-gap but plan for a replacement part.

6) Tighten surrounding screws:

– Lightly snug any visible Torx screws that secure the base and pedal bracket. Do not overtighten—Dyson plastic can crack.

Testing

- Without the head on, raise the handle upright and listen for the lock. It should still click. If it clicks now but not with the head attached, the head alignment is affecting it—ensure the head is fully seated and level.

Method 4: Replace the Upright Lock/Latch Spring or Pedal Assembly (30–45 minutes)

If the latch spring is weak or broken, the vacuum will not reliably stand upright.

Diagnosing the Issue

- No click at all even after cleaning.

- Pedal doesn’t return; the lock only engages if you manually push the latch.

- Visible broken spring or damaged latch.

Fix Steps

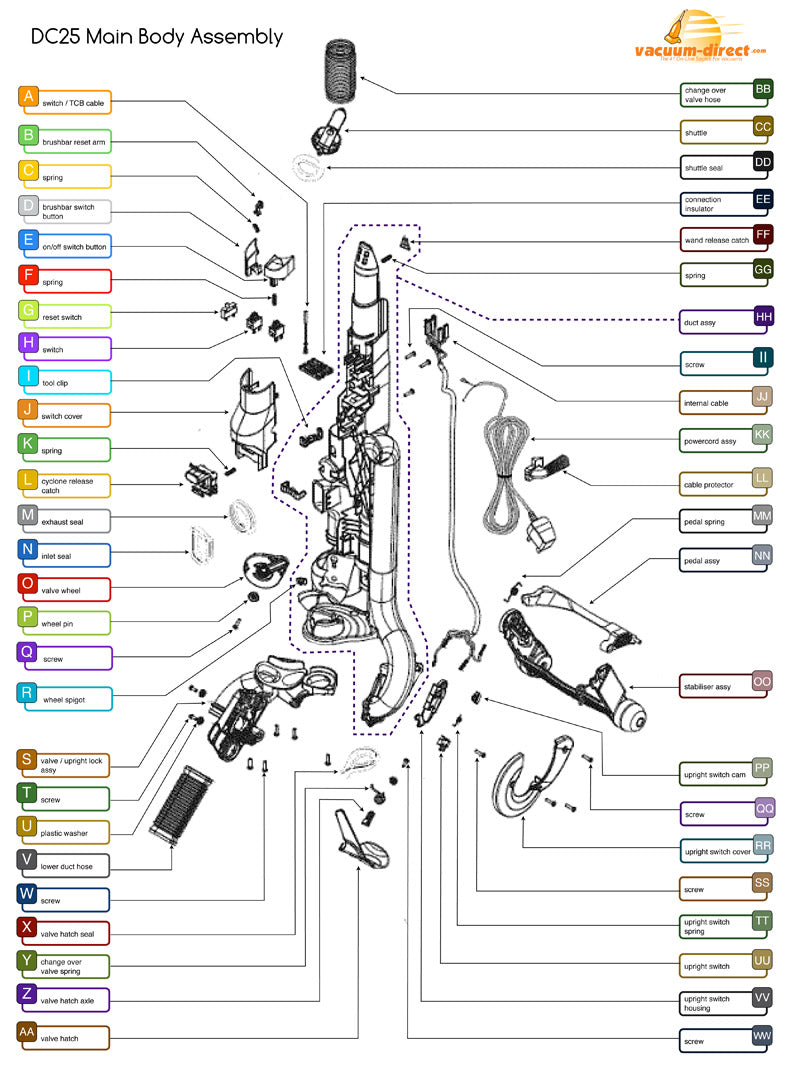

1) Identify parts:

– Search for “Dyson DC25 upright lock assembly,” “recline pedal,” or “DC25 latch spring.” Part names vary by supplier.

2) Tools:

– Torx T10/T15 driver, small flat screwdriver, needle-nose pliers.

3) Disassembly:

– Unplug, remove bin/cyclone and cleaner head.

– Remove screws securing the rear pedal bracket and base cover (locations vary slightly by sub-model, e.g., DC25 All Floors, Animal, Multi Floor).

– Carefully lift the cover to expose the latch and spring.

4) Replace spring/latch:

– Note spring orientation with a photo.

– Swap in the new spring/latch. Ensure the spring’s legs are seated in the correct slots so the latch returns to lock position.

5) Reassemble:

– Refit the base cover and screws.

– Reattach the cleaner head and bin/cyclone until everything clicks.

Testing

- Stand the machine up. A crisp click should hold the handle.

- Press the pedal to recline; it should release smoothly and re-lock afterward.

How to Prevent Future Upright Lock Issues

- Keep the latch area clean: Monthly, invert the vacuum and brush out dust around the pedal and latch.

- Avoid dragging by the handle when not reclined: Always press the pedal before pulling back.

- Don’t lean the machine on soft carpets when storing: Store on a hard surface to reduce stress on the latch.

- Periodically lube the pivot points: A tiny spritz of silicone every 3–4 months prevents binding.

- Ensure full assembly seating: After cleaning, firmly click the cleaner head and bin back in to maintain alignment.

Pro Tips

- Use compressed air sparingly: Short bursts prevent forcing debris deeper into the mechanism.

- Mark screw locations: Take photos as you go to avoid mixing different screw lengths.

- Check the brush head neck: If the neck is skewed or cracked, it can prevent the handle from reaching true vertical and engaging the lock.

- Replace worn wheels: Ovalized or wobbly rear wheels can throw off latch geometry.

- Avoid oil-based lubricants: They attract dust and accelerate sticking.

- Test without the head: If it locks without the cleaner head attached, the alignment issue is in the head/neck assembly.

- Keep hair away from pivots: After vacuuming long hair or pet hair, check the pedal area—hair wraps here just like on the brush bar.

When to Call a Professional

- The pedal bracket or ball housing is cracked.

- The latch won’t engage even after spring replacement.

- You’re uncomfortable disassembling the base or dealing with springs.

- The vacuum also has electrical issues or error lights.

What to look for:

– Dyson-authorized repair centers or experienced independent vacuum shops.

– Warranty status: DC25 models are older and often out of warranty, but check if you have store protection plans.

– Typical costs:

– Cleaning/lubrication: $30–$60

– Pedal/latch/spring replacement: $60–$120 parts and labor

– Major base/ball housing replacement: $120–$180

FAQ

Q: Why won’t my Dyson DC25 click into upright position?

A: The upright locking latch is likely stuck with debris, the recline pedal linkage isn’t returning, or the latch spring is weak or broken. Cleaning, lubricating, and checking the linkage usually restores the click.

Q: Can I fix the upright lock without taking the vacuum apart?

A: Often yes. Press the recline pedal repeatedly, remove debris around the pedal and wheels, and gently guide the head while lifting the handle to lock. If that fails, a light clean/lube of the latch area is the next step.

Q: What lubricant should I use on the DC25 latch?

A: Use a dry silicone or PTFE spray. Avoid oils or grease, which attract dirt and can worsen sticking.

Q: The handle locks only sometimes. What should I check?

A: Intermittent locking points to a sticky latch or weak spring. Clean and lube first. If the problem returns quickly, replace the latch spring or the entire pedal/latch assembly.

Q: My DC25 locks without the cleaner head but not with it attached. Why?

A: The head/neck may be misaligned or not clicking in fully, preventing the handle from reaching true upright. Re-seat the head, check for cracks in the neck, and ensure the head pivots freely.

Q: Is this issue common on DC25 models?

A: Yes. With age, debris buildup and spring fatigue make the upright lock a common maintenance item on the DC25.

Q: Could the ball assembly be causing the problem?

A: Yes. Debris or damage inside the ball near the cam can block the latch path. Cleaning that area or replacing worn parts often resolves it.

Alternative Solutions

If repairs aren’t cost-effective or parts are hard to source, consider these alternatives:

| Solution | Pros | Cons | Best For |

|---|---|---|---|

| Replace latch/pedal assembly | Restores original function; low cost | Requires disassembly | DIYers comfortable with tools |

| Use a wall bracket/stand | No repair needed; quick | Doesn’t fix root cause | Temporary storage solution |

| Upgrade to newer Dyson model (Ball Animal, Multi Floor) | New warranty, improved design | Higher cost | Heavily used homes/pets |

| Professional repair service | Expert diagnosis; warranty on work | Service fees | Users short on time or tools |

Get Your Dyson DC25 Working Again

By following this guide, you can fix a Dyson DC25 that won’t stand upright:

– Quick pedal reset and debris removal

– Clean and lubricate the upright latch and pedal pivots

– Inspect and realign the recline linkage

– Replace the latch spring or pedal assembly if worn

Don’t let a simple latch keep your vacuum from working properly. Start with the quick steps and work your way up—most people restore the upright lock with a thorough clean and a dab of silicone lube.

Have you fixed your Dyson DC25 not standing upright? Share what worked for you in the comments—your tips can help other Dyson owners get back to cleaning with confidence.