If your Dyson vacuum turbo head isn’t spinning or picking up debris like it used to, you’re not alone. It’s frustrating when the brush bar stops working mid-clean, especially on carpets. The quick fix? Turn the vacuum off, remove the floor head, clear any hair or debris around the brush bar and end caps, and press the reset button (if your model has one). This simple reset resolves many “Dyson turbo head not working” issues in minutes.

In this guide, you’ll get a complete, step-by-step approach to diagnosing and fixing a non-spinning turbo head on Dyson uprights, canisters, and cordless models (V7, V8, V10, V11, V12, V15, Ball Animal, Cinetic, and more). You’ll learn the most common causes, multiple repair methods from easy to advanced, how to prevent future issues, and when to call in professional help.

Common Causes of a Dyson Turbo Head Not Working

- Tangled hair or string around the brush bar or bearings

- Blocked air pathways in the turbo head or wand

- Power supply issues to the head (cord break, poor contact, or low battery)

- Tripped brush bar overload or missing reset

- Worn or seized end-cap bearings

- Damaged drive belt (for belt-driven heads)

- Faulty motor/PCB inside the motorized head

- Debris in sensor or clutch mechanisms (on select models)

- Incorrect cleaning mode (Eco mode on cordless may slow the head)

- Debris lodged in the turbine (for air-driven “turbine” heads)

How to Fix a Dyson Vacuum Turbo Head Not Working

Method 1: Quick Clean and Reset (Fastest Fix)

Estimated time: 5–10 minutes

Diagnosing the Issue

- Brush bar not spinning but suction works

- Head stops when contacting carpet but runs in the air

- Clicking sound or pulsing from the head

- Light on the head flashing (cordless motorized heads)

Fix Steps

-

Power Off and Unplug

– For corded: Unplug the vacuum.

– For cordless: Remove the battery if possible.

– Important: Avoid accidental activation while fingers are near the brush. -

Remove the Floor Head

– Detach the turbo head from the wand/handle. On cordless models, press the red button; on uprights, release the head by the quick-release catch. -

Clear Hair and Fibers

– Cut away any hair, threads, or pet fur wrapped on the brush bar using scissors. Work carefully to avoid cutting bristles.

– Remove debris from the brush bar slot and edges. -

Open End Caps and Check Bearings

– Many Dyson heads (V7–V15, Ball Animal) have a coin-lock to release the brush bar. Turn the lock, slide the brush bar out.

– Pull off end caps; clear out hair wound around the shafts/bearings. Spin bearings by hand—if gritty or stuck, clean and lubricate lightly with a drop of sewing machine oil. -

Check for Blockages

– Look through the head’s air channels. Remove clogs in the neck, brush housing, and mini turbine (if equipped).

– Check the wand and bin inlet for blockages that could overload the head. -

Reset the Brush Bar

– Some models have a reset button on the head or near the motor housing. Press firmly.

– On cordless, toggle the power modes: switch from Eco to Auto/Med or Boost; then turn off and on again. -

Reassemble and Test

– Refit the brush bar and end caps, lock with the coin-lock.

– Reattach head to the wand and test on both hard floor and carpet.

Testing

- Brush should spin continuously on carpet without stopping.

- No clicking or pulsing.

- If lights on head were flashing, they should be solid/normal now.

Method 2: Power and Contact Checks (Electrical Path)

Estimated time: 10–15 minutes

Diagnosing the Issue

- Brush bar not spinning after cleaning

- Head light flickers or doesn’t light up

- Works intermittently when twisting the wand

Fix Steps

-

Verify Power Mode and Battery (Cordless)

– Ensure battery is adequately charged (>30%). Weak batteries may fail to drive the head.

– Try a different mode: Auto/Med for carpet, Boost briefly for testing. -

Inspect Electrical Contacts

– Clean the metal contacts on the head, wand ends, and main body using a dry cloth or contact cleaner. Oxidized contacts can interrupt power.

– Ensure the wand clicks solidly into place. Loose fit causes intermittent operation. -

Check the Wand Continuity (Cordless/Stick)

– If you have a spare wand or can borrow one, swap and test. Wand wiring can break internally from repeated flexing.

– Gently flex the wand while running; if the head starts/stops, suspect a broken internal conductor—replace the wand. -

Upright Models: Head Cable and Switch

– Check the brush control switch position (some Dyson uprights have a brush on/off switch).

– Inspect the cable leading to the head for damage or pinches. If the head runs only at certain angles, the cable may be fractured. -

Reset Overload/Clutch (If Equipped)

– Some uprights have a clutch or overload system that disengages if the brush jams. After clearing, power off for 30 seconds, then restart with the head lifted and activate the brush switch.

Testing

- Head should start immediately when power/mode is engaged.

- Wiggle test: move the wand and hose—brush should not cut out.

Method 3: Deep Service of the Turbo Head (Bearings, Belt, Turbine)

Estimated time: 20–40 minutes

Diagnosing the Issue

- Brush spins stiffly by hand or not at all

- Burning smell, squealing, or grinding noise

- Head stalls on medium pile carpet

- On turbine heads (air-driven), brush spins in the air but stops on carpet

Fix Steps

-

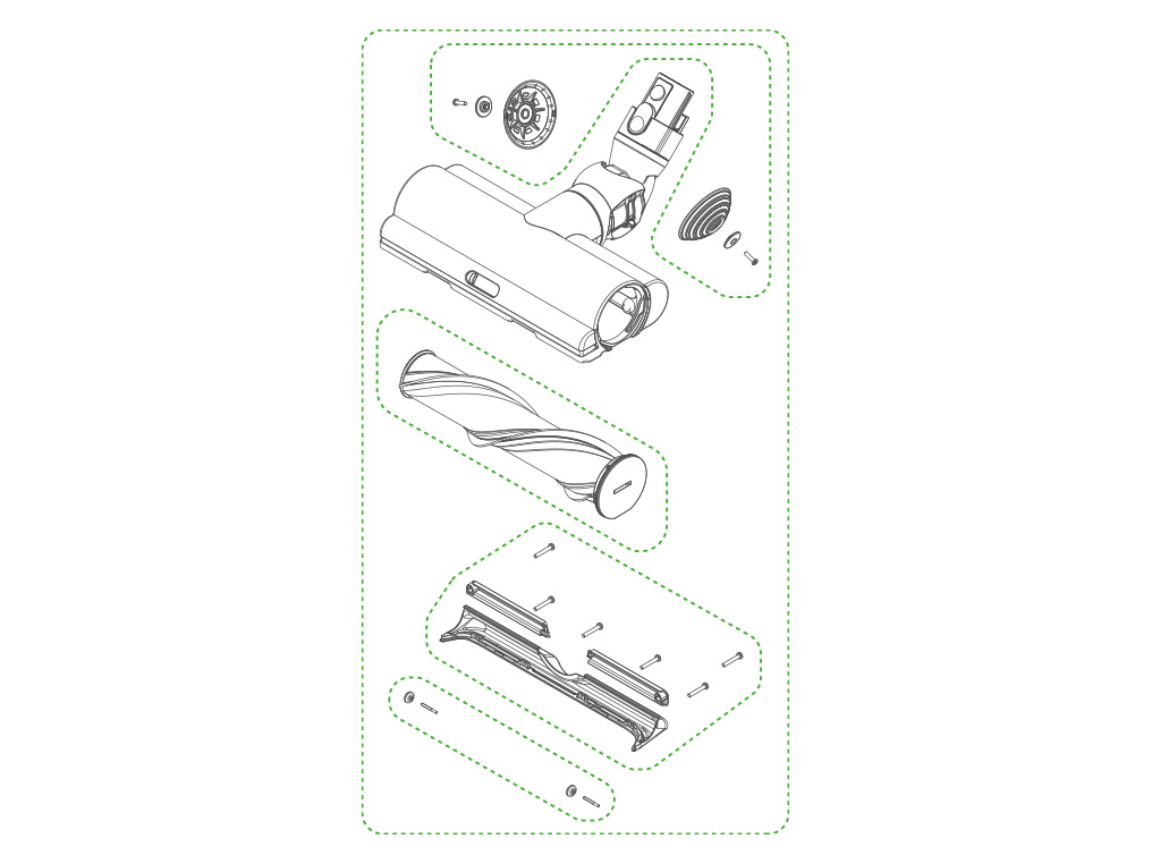

Disassemble the Head

– Remove brush bar and end caps.

– On some models, remove Torx screws (T8–T10 common) to split the housing. Keep track of screw locations. -

Clean and Service Bearings

– Pull bearings from both ends of the brush bar (if removable).

– Remove hair, clean with isopropyl alcohol, dry, then apply a tiny drop of light oil.

– If bearings are rough or seized, replace. Many third-party brush bar bearing kits exist for V7–V11 and Ball heads. -

Inspect and Replace Belt (If Belt-Driven)

– Some older Dyson heads and certain canister turbo tools use a drive belt.

– Check for cracks, glazing, or slack. Replace if stretched or snapped. Note the routing before removal. -

Turbine/Air-Driven Heads

– Open the mini turbine tool or air-driven head.

– Clear debris in the turbine fan and gear chamber. Any hair here dramatically reduces torque.

– Ensure the turbine spins freely by blowing through and spinning by hand. -

Motorized Heads: PCB/Motor Check

– Look for debris or moisture inside the motor compartment.

– Inspect for burnt smell, scorch marks, or broken wires.

– Important: Do not run the motor open outside the housing for long—risk of damage. -

Reassemble Carefully

– Refit gears/belts correctly.

– Ensure seals and covers are seated—air leaks reduce brush torque.

Testing

- Brush should spin freely by hand.

- On carpet, the head should maintain rotation without squealing or stalling.

Method 4: System-Level Checks (Airflow, Filters, Modes)

Estimated time: 10–20 minutes

Diagnosing the Issue

- Pulsing or surging when head is attached

- Good suction without the head, but stalls with it

- Head light flashing error code on cordless

Fix Steps

-

Clear All Air Pathways

– Empty the bin; check cyclone inlet.

– Remove clogs in the wand and the hose. A blocked system can cause pulsing and head shutdown. -

Wash or Replace Filters

– Wash pre-motor filters (e.g., V7/V8 purple top, V10/V11 single-piece) with cold water only; dry 24 hours minimum.

– Replace HEPA/post-motor filters if smells persist or airflow remains weak.

– Note: Running with damp filters can trip overload and harm the motor. -

Choose the Right Mode

– For deep carpets, use Auto/Med or Boost briefly. Eco may not provide enough torque for some motorized heads.

– On uprights, ensure the brush control is ON and the head is reclined; many models disable the brush when upright. -

Check Height Adjustment (Uprights)

– If your Dyson has height settings, lift the head one level for thick carpets to reduce drag.

Testing

- Attach head and run; no pulsing, steady suction, and consistent brush rotation.

Prevention Tips and Maintenance Advice

- Clean the brush bar weekly if you have pets or long hair in the home.

- Remove the head after every few cleans to clear the neck and wand opening.

- Wash filters every 1–3 months (model-dependent) and always dry fully.

- Avoid vacuuming shoelaces, wired toys, rug fringe, or long fibers—these jam the brush.

- Store the vacuum without bending the wand sharply to protect internal conductors.

- Use the correct mode for the surface; avoid prolonged Boost to prevent overheating.

- Periodically lubricate end-cap bearings with a tiny drop of light oil if they squeak.

Model-Specific Notes for Dyson Turbo Heads

Dyson V7/V8/V10/V11/V12/V15 Cordless

- Brush reset: Cycle power and switch modes; some heads auto-reset after a jam is cleared.

- Wand wiring failure is common with age; swapping wands is a quick diagnosis.

- Soft Roller (Fluffy) heads don’t have a bristled bar but can still jam with fibers at axle points.

Dyson Ball Animal, Multi Floor, Cinetic (Uprights)

- Ensure the machine is reclined; brush bar is disabled when upright.

- Brush bar switch must be ON; check if indicator light is lit.

- Clutch/overload may need a power cycle after clearing jams.

Canister Models with Turbine/Carbon Fiber Turbine Heads

- Air-driven heads rely on airflow; any system blockage will stall the brush.

- Thoroughly clean the turbine fan and gears for full power.

Pro Tips

- Keep a seam ripper in your cleaning caddy; it’s perfect for cutting hair off the brush quickly.

- Mark the coin-lock direction on your head with a small sticker for faster disassembly.

- If the head stops on thick rugs, angle the head slightly and take shorter passes to prevent overload.

- After washing filters, leave them in a warm, ventilated area for a full 24–48 hours—hidden moisture causes persistent pulsing and head cutouts.

- Use compressed air (gently) to blow dust out of the head’s sensor and PCB areas—avoid spinning the brush with high-pressure air.

- If you smell burning or see smoke, stop immediately; continuing to run can destroy the head motor.

- Keep a spare filter and, if cordless, a spare battery to minimize downtime.

Professional Help

- Signs you need service:

- Persistent non-spinning brush after cleaning and resets

- Electrical burning smell, melted plastic, or excessive heat

- Head only works at certain wand angles (likely wiring failure you can’t resolve)

- Loud grinding from bearings even after cleaning/lubrication

-

Visible damage to PCB or motor

-

What to look for in a service provider:

- Dyson-authorized or experienced with Dyson parts

- Uses genuine or high-quality compatible parts

-

Provides diagnostic quote and warranty on repairs (30–90 days)

-

Typical cost ranges:

- Replacement brush bar/bearings: $15–$40

- Wand replacement (cordless): $30–$80

- Motorized head assembly: $70–$180+ depending on model

-

Professional labor: $60–$120/hour

-

Warranty considerations:

- Dyson warranties vary by model (usually 2 years for cordless, 5 years for select uprights). Opening the head beyond user-serviceable parts may affect coverage. Check your original paperwork or Dyson support before deep disassembly if under warranty.

FAQ

Q: Why does my Dyson brush bar stop on carpet but spin in the air?

A: The brush is encountering resistance from hair wrapping, seized end bearings, or too low a height setting. Clear the brush and bearings, check for blockages, and use Auto/Med mode or raise the head height on uprights.

Q: My Dyson head clicks and the light flashes. What does that mean?

A: That typically indicates a jam or overload. Turn off power, remove the head, clear hair/debris, press the reset (if present), and ensure the head and wand contacts are clean and fully seated.

Q: Can a low battery cause the turbo head not to work?

A: Yes. On cordless models, a weak battery may run suction but not supply enough current to the brush motor. Fully charge or try a known-good battery before deeper repairs.

Q: How often should I clean the Dyson brush bar?

A: For homes with pets or long hair, weekly is ideal. Otherwise, every 2–4 weeks. Regular maintenance prevents overloads and premature motor wear.

Q: My air-driven turbine head slows down on rugs. Is it faulty?

A: Not necessarily. Air-driven heads rely entirely on airflow; thick rugs reduce airflow and torque. Ensure the vacuum is unclogged, filters are clean, and consider a motorized head for heavy carpets if compatible.

Q: Is it safe to lubricate the brush bar bearings?

A: Yes, but use only a small drop of light oil on metal bearings and avoid getting oil on the brush or belt. If bearings are sealed or severely worn, replacement is better.

Q: Do I need special tools to open the Dyson head?

A: Usually, a coin for the brush lock and a small Torx driver (T8–T10) for screws. Keep screws organized by position.

Alternative Solutions

Sometimes repair isn’t cost-effective, especially if the head motor or PCB is burnt out. Consider these options:

| Solution | Pros | Cons | Best For |

|---|---|---|---|

| Replace with OEM Dyson head | Perfect fit, optimal performance | Higher cost | Users under warranty or seeking original quality |

| High-quality compatible head | Lower cost, good performance | May have shorter lifespan, varying quality | Budget-conscious users |

| Switch to a Soft Roller (Fluffy) for hard floors | Exceptional hard-floor pickup | Not ideal for carpet | Homes with mostly hard flooring |

| Use non-motorized turbine tool | No electrical parts to fail | Lower deep-cleaning performance | Low-pile rugs, quick cleanups |

Get Your Dyson Turbo Head Working Again

By following this guide, you have multiple proven ways to fix a Dyson vacuum turbo head not working:

– Quick clean, jam removal, and brush reset

– Power path and contact checks across head, wand, and body

– Deep servicing of bearings, belts, and turbine components

– System-level airflow and filter maintenance to prevent overloads

– Professional repair or replacement options when necessary

Don’t let a stalled brush derail your cleaning routine. Work through these methods in order, and you’ll restore strong, reliable brush bar performance and extend the life of your Dyson.

Have you fixed your Dyson turbo head with these steps? Share what worked for your model in the comments to help other readers. Found this helpful? Bookmark it for next time.